Mechanical fixture with optimized ergonomics for function an incirciut test.

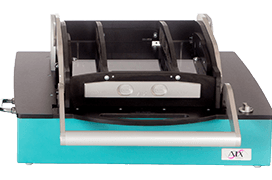

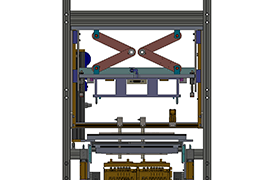

MMI - Man Machine Interface

With the MMI from ATX, you have the ideal fixture solution for function test, final test and ICT applications for up to 1600N (approximately 800 needles at 2N). Our new system combines optimal ergonomics with high performance, durability and precision, ensuring your investment over the long term. Another benefit of the MMI - it is prepured for a safety switch with guard locking, and an electrical interlock.

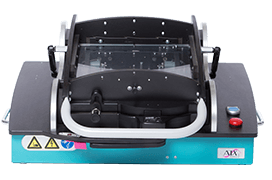

Electromechanical fixture

The MEE offers with its controllable multi-level functionality the highest flexible applicability. The UUT can be touched in various heights in multi steps. Typically used for Bi-level, a 3rd level can be realized. Like all our ME and MMI fixtures the MEE fits optimal the needs for functional- and ICT test up to 500 probes (2N).

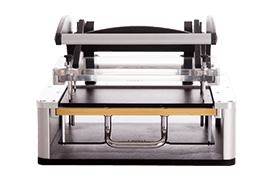

Linear Arm Fixtrues

Your solution with minimal space requirements for trouble-free and low-cost implementation of small-scale operations such as flash programming or small functional tests for up to approx. 100 probes 2N. Offering considerable cost savings with small assembly groups and manageable quantities. The LHS² is the optimized successor of the proven LHS system and convinces by its robust design and the resulting high cycle resistance. Also high production quantities can be managed by these devices. The new bearing and lever have a positive effect on the maintenance and ergonomics. The open position of the contact pressure mechanism is secured by magnets impeding the undesired closing. Also the pneumatic and electric optional locking options are an innovation.

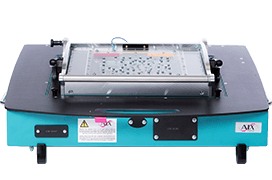

Vacuum fixtures

Even before you decide to make your purchase flexibility is the greatest benefit, because the device is available in all stages of assembly and for all test systems currently on the market. From Acculogic/ Scorpion, Aeroflex and Keysight/ Agilent/ HP via Digitaltest, Reinhardt, Rhode & Schwarz to Spea, Teradyne/Genrad, TRI, Dr. Eschke and many more – you only need to name your requirements and your new vacuum fixture will come to you fully fitted with probes, wired and tested. Alternatively it can be supplied only drilled and fitted with probes, only drilled or as a basic kit. Optionally also available in a bi-level version and/or for contacting on both sides.

ATX also supplies high quality basic kits in various sizes, on request modified and with the accessories as specified by the customer. Accessories which can be supplied range from push fingers, vacuum lids and mechanical pressure units to plug-contact modules, boardmarkers, sensor and probe material, setting tools and a range of further tooling.

In-line fixtures

Pneumatic fixtures

The MEP is a pneumatic stand-alone fixture for functional testing, final testing and small-scale ICT applications of up to approx. 500 probes 2N. This unit enables you to increase your cycle numbers and probe capacity without having to apply significant power. Our MEP represents fatigue-free operation. The lid opens automatically and enables the fast replacement of defective parts. Thanks to its compact construction and space-saving mechanism it can be flexibly combined with many additional components. A special feature which is only available from ATX: the MEP also offers bi-level capability. Quality and reliable functioning in continuous operation: ATX tested the MEP with more than 1 million operations under full load, an examination which the unit passed with flying colours, making it ideally suited to your large-scale production.

Fine-pitch fixtures

HF-fixtures

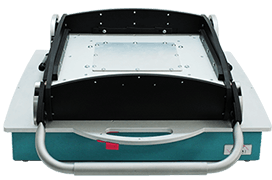

Special rules apply when it comes to checking and testing high-frequency and radio assembly groups. Here it is a question of reliably shielding the devices to be tested against radiation interference from their surroundings. At the same time these tests must not be allowed to affect the surroundings themselves.

Our electromagnetically shielded MEHF fixture for high-frequency applications offers you the perfect solution. It enables you to carry out in-depth testing of sensitive, highly sensitive and transmitting assembly groups – even those consisting of a combination of transmitter and receiver, without risking consequences for your production environment. And of course without subjecting your delicate assembly groups to possible radiation interference from their surroundings.

Our electromagnetically shielded MEHF fixture for high-frequency applications offers you the perfect solution. It enables you to carry out in-depth testing of sensitive, highly sensitive and transmitting assembly groups – even those consisting of a combination of transmitter and receiver, without risking consequences for your production environment. And of course without subjecting your delicate assembly groups to possible radiation interference from their surroundings.

In the MEHF fixture by ATX the probe bed is shielded completely both above and below the probes by a Faraday cage made of aluminium. The opening lid also has reliable HF sealing. All measuring lines reach the exterior via filtered plugs. By simply closing the lid the assembly groups can be contacted simultaneously.ass:

The MEHF is not just an innovative and technologically superior concept, it is also a simple, robust and functional solution on the basis of a low-cost standard kit. The pressure mechanism of our MEHF applies the tried-and-tested ME technology by ATX. The outstanding functionality and solidity of our mechanical fixtures is the basis for the unit's development and will offer you new dimensions in performance, load capacity and availability.